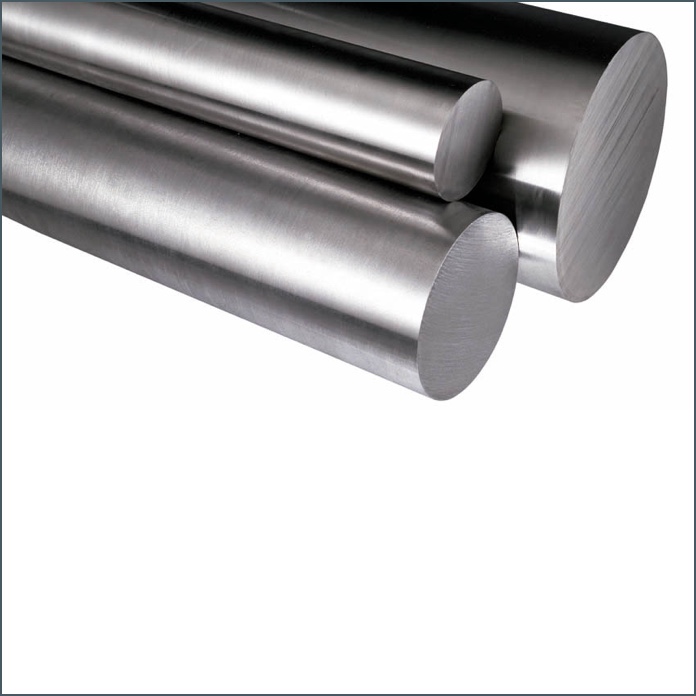

Macplus® Cold-Finished Bars

Gerdau produces Macplus® cold-finished bars at four manufacturing facilities in North America. Macplus® bars are turned and polished to provide a uniform defect-free, decarb-free, and scale-free, bright surface with tight size tolerances and concentricity that can improve machinability up to 30%. MACPLUS® bars are available in all carbon and alloy grades and can also be metallurgically tailored to suit our customer's particular requirements.

Product Information

Sizes

- Diameter from 7/8” to 5”

- Lengths ranging from 10’ to 32’

Grades

- Carbon and alloy ASTM grades and customized SBQ chemistries, including bearing and aircraft quality

Heat Treating

- Full range of in-house heat treating capabilities, including spheroidizing, normalizing, stress relieving, annealing, quench and tempering, and any customized heat treat cycles

Inspection

- In-house automatic straightening, surface and ultrasonic internal inspection

Other Attributes

- Automatic end chamfering available

Critical Applications:

Show pictures of the applications, such as wheel hub and spindles, transmissions and differential gears and shafts, semi and full float axles, crankshafts, camshafts, connecting rods, constant velocity joints, transmission pulleys, coils springs and stabilizer bars. Other market applications would include landing gear components, bearings, sucker rods, drill collars, drill pipes, tank track parts, firearms and pressure tubing.

Critical Applications +